PACC By Vitra

Swivel fabric office chair with armrests

Apple Shopping Event

Hurry and get discounts up to 20% Read more

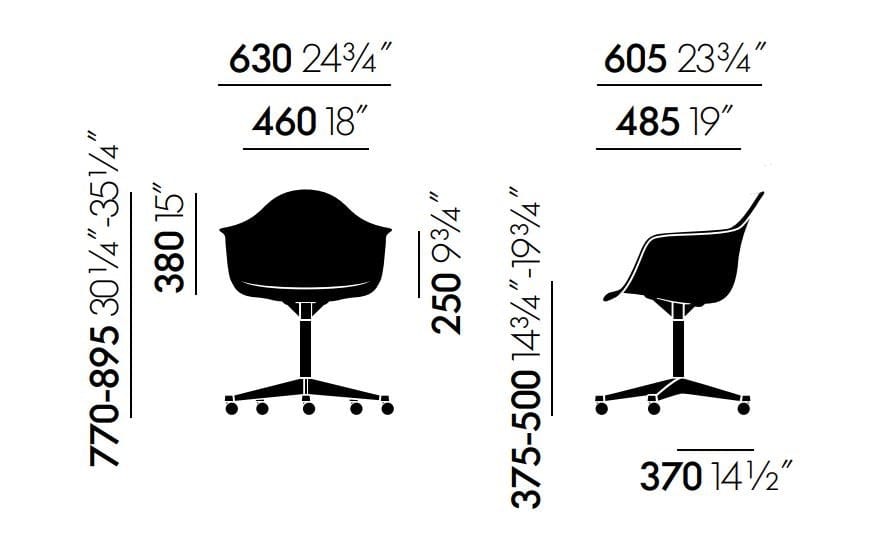

Thanks to the large selection of bases, the Plastic Chairs by Charles and Ray Eames can be used in a wide range of different settings. For example, the PACC (Pivot Armchair Cast Base on Castors), with its height-adjustable swivel-mount base, is ideal for use in informal office spaces and studio offices. The various colour and upholstery options make it easy to find the right chairs for all types of environments.

Material description

– Seat shell: dyed-through polypropylene. All models are available with a seat cushion (screwed to the seat shell) or full upholstery. The fully upholstered version has moulded polyurethane foam padding covered in fabric, attached to the shell with a welted edge. Different shell and upholstery colours and various bases provide a multitude of possible combinations.

– Options: the Eames Plastic Chair is available as a visitor chair, dining chair, rocking chair, swivel chair or in stacking versions and with ganging brackets for row seating. Beam-mounted shells are suited for use in waiting areas.

– Base: five-star base in polished die-cast aluminium with double castors in basic dark. (PACC = Pivot Armchair Cast Base on Castors)

From January 2024 the shells of the Eames Plastic Chairs from Vitra are now made of recycled post-consumer plastic. These chairs are known as Eames Plastic Chairs RE. The recycling material stems from Germany’s ‘Yellow Bag’ (Gelber Sack) collection of household waste, which primarily consists of used packaging. Utilising this recyclate instead of conventional plastic generates fewer climate-damaging emissions and significantly reduces energy consumption.

Due to the composition of the recycled materials, the different colour versions of the seat shells are interspersed with tiny specks of pigment.

‘Getting the most of the best to the greatest number of people for the least’: with these words, Charles and Ray Eames described one of their main goals as furniture designers. None of their other designs come as close to achieving this ideal as the Plastic Chairs. For years, the designer couple explored the fundamental idea of a one-piece seat shell moulded to fit the contours of the human body. After experiments with plywood and sheet aluminium in the 1940s produce unsatisfactory results, their search for alternative materials led them to glass-fibre reinforced polyester resin.

The Eameses recognised and fully exploited the advantages of the material: mouldability, rigidity, pleasant tactile qualities, suitability for industrial manufacturing methods. With this material, which was previously unknown in the furniture industry, they successfully developed the shell designs for serial production. After their debut at the ‘Low-Cost Furniture Design’ competition organised by the Museum of Modern Art in 1948, the Plastic Armchair (A-shell) and Plastic Side Chair (S-shell) were launched on the market in 1950 as the very first mass-produced plastic chairs in the history of furniture.

The Eames Plastic Chairs also introduced a new furniture typology that has since become widespread: the multifunctional chair whose shell can be joined with a variety of different bases to serve diverse purposes. As early as 1950, Charles and Ray Eames presented a series of bases that enabled various sitting positions. An especially striking model is the so-called Eiffel Tower base an intricate and graceful design made of steel wire that inimitably combines light, elegant forms with structural strength.

Today Vitra manufactures the comfortable seat shells of the Eames Plastic Chairs in polypropylene, while those of the Eames Fiberglass Chairs are produced in glass-fibre reinforced polyester resin. There is also a wide choice of bases and shell colours, along with upholstery options for some models. This allows customers to specify countless different combinations and to use the chairs in the widest range of settings from dining rooms, living rooms and home offices to office workspaces and conference rooms; from restaurants and cafs to break rooms and cafeterias; from waiting areas and auditoriums to terraces and gardens.

In 2016, Vitra added roughly 20 mm to the base height of the Eames Plastic Chairs DSX, DAX, DSR, DAR, DSW and DAW while adapting the seat geometry accordingly.

Authorities in our business will tell in no uncertain terms that Lorem Ipsum is that huge, huge no no to forswear forever. Not so fast, I'd say, there are some redeeming factors in favor of greeking text, as its use is merely the symptom of a worse problem to take into consideration.

Anyway, you still use Lorem Ipsum and rightly so, as it will always have a place in the web workers toolbox, as things happen, not always the way you like it, not always in the preferred order.

Request a Quote

Average response time is approximately 30 minutes

PACC By Vitra

Get In Touch With Us

Italcasa Furniture & Interior Design

32968 Woodward Ave,

Royal Oak, MI 48073

Mon - Fri 10 a.m. - 05 p.m.

Sat - Sun 11 a.m. - 04 p.m.

Italcasa Design - Michigan Design Center

1700 Stutz Dr suite 30,

Troy, MI 48084

Mon - Fri 10 a.m. - 05 p.m.

Sat - Sun 11 a.m. - 04 p.m.

Product details

Made possible by exploring innovative molded plywood techniques, Iskos-Berlin’s Soft Edge Chair blends strong curves with extreme lightness to create a three-dimensionality not usually possible with 2-D plywood.

Description

Thanks to the large selection of bases, the Plastic Chairs by Charles and Ray Eames can be used in a wide range of different settings. For example, the PACC (Pivot Armchair Cast Base on Castors), with its height-adjustable swivel-mount base, is ideal for use in informal office spaces and studio offices. The various colour and upholstery options make it easy to find the right chairs for all types of environments.

Material description

– Seat shell: dyed-through polypropylene. All models are available with a seat cushion (screwed to the seat shell) or full upholstery. The fully upholstered version has moulded polyurethane foam padding covered in fabric, attached to the shell with a welted edge. Different shell and upholstery colours and various bases provide a multitude of possible combinations.

– Options: the Eames Plastic Chair is available as a visitor chair, dining chair, rocking chair, swivel chair or in stacking versions and with ganging brackets for row seating. Beam-mounted shells are suited for use in waiting areas.

– Base: five-star base in polished die-cast aluminium with double castors in basic dark. (PACC = Pivot Armchair Cast Base on Castors)

From January 2024 the shells of the Eames Plastic Chairs from Vitra are now made of recycled post-consumer plastic. These chairs are known as Eames Plastic Chairs RE. The recycling material stems from Germany’s ‘Yellow Bag’ (Gelber Sack) collection of household waste, which primarily consists of used packaging. Utilising this recyclate instead of conventional plastic generates fewer climate-damaging emissions and significantly reduces energy consumption.

Due to the composition of the recycled materials, the different colour versions of the seat shells are interspersed with tiny specks of pigment.

‘Getting the most of the best to the greatest number of people for the least’: with these words, Charles and Ray Eames described one of their main goals as furniture designers. None of their other designs come as close to achieving this ideal as the Plastic Chairs. For years, the designer couple explored the fundamental idea of a one-piece seat shell moulded to fit the contours of the human body. After experiments with plywood and sheet aluminium in the 1940s produce unsatisfactory results, their search for alternative materials led them to glass-fibre reinforced polyester resin.

The Eameses recognised and fully exploited the advantages of the material: mouldability, rigidity, pleasant tactile qualities, suitability for industrial manufacturing methods. With this material, which was previously unknown in the furniture industry, they successfully developed the shell designs for serial production. After their debut at the ‘Low-Cost Furniture Design’ competition organised by the Museum of Modern Art in 1948, the Plastic Armchair (A-shell) and Plastic Side Chair (S-shell) were launched on the market in 1950 as the very first mass-produced plastic chairs in the history of furniture.

The Eames Plastic Chairs also introduced a new furniture typology that has since become widespread: the multifunctional chair whose shell can be joined with a variety of different bases to serve diverse purposes. As early as 1950, Charles and Ray Eames presented a series of bases that enabled various sitting positions. An especially striking model is the so-called Eiffel Tower base an intricate and graceful design made of steel wire that inimitably combines light, elegant forms with structural strength.

Today Vitra manufactures the comfortable seat shells of the Eames Plastic Chairs in polypropylene, while those of the Eames Fiberglass Chairs are produced in glass-fibre reinforced polyester resin. There is also a wide choice of bases and shell colours, along with upholstery options for some models. This allows customers to specify countless different combinations and to use the chairs in the widest range of settings from dining rooms, living rooms and home offices to office workspaces and conference rooms; from restaurants and cafs to break rooms and cafeterias; from waiting areas and auditoriums to terraces and gardens.

In 2016, Vitra added roughly 20 mm to the base height of the Eames Plastic Chairs DSX, DAX, DSR, DAR, DSW and DAW while adapting the seat geometry accordingly.

Description

Thanks to the large selection of bases, the Plastic Chairs by Charles and Ray Eames can be used in a wide range of different settings. For example, the PACC (Pivot Armchair Cast Base on Castors), with its height-adjustable swivel-mount base, is ideal for use in informal office spaces and studio offices. The various colour and upholstery options make it easy to find the right chairs for all types of environments.

Material description

– Seat shell: dyed-through polypropylene. All models are available with a seat cushion (screwed to the seat shell) or full upholstery. The fully upholstered version has moulded polyurethane foam padding covered in fabric, attached to the shell with a welted edge. Different shell and upholstery colours and various bases provide a multitude of possible combinations.

– Options: the Eames Plastic Chair is available as a visitor chair, dining chair, rocking chair, swivel chair or in stacking versions and with ganging brackets for row seating. Beam-mounted shells are suited for use in waiting areas.

– Base: five-star base in polished die-cast aluminium with double castors in basic dark. (PACC = Pivot Armchair Cast Base on Castors)

From January 2024 the shells of the Eames Plastic Chairs from Vitra are now made of recycled post-consumer plastic. These chairs are known as Eames Plastic Chairs RE. The recycling material stems from Germany’s ‘Yellow Bag’ (Gelber Sack) collection of household waste, which primarily consists of used packaging. Utilising this recyclate instead of conventional plastic generates fewer climate-damaging emissions and significantly reduces energy consumption.

Due to the composition of the recycled materials, the different colour versions of the seat shells are interspersed with tiny specks of pigment.

‘Getting the most of the best to the greatest number of people for the least’: with these words, Charles and Ray Eames described one of their main goals as furniture designers. None of their other designs come as close to achieving this ideal as the Plastic Chairs. For years, the designer couple explored the fundamental idea of a one-piece seat shell moulded to fit the contours of the human body. After experiments with plywood and sheet aluminium in the 1940s produce unsatisfactory results, their search for alternative materials led them to glass-fibre reinforced polyester resin.

The Eameses recognised and fully exploited the advantages of the material: mouldability, rigidity, pleasant tactile qualities, suitability for industrial manufacturing methods. With this material, which was previously unknown in the furniture industry, they successfully developed the shell designs for serial production. After their debut at the ‘Low-Cost Furniture Design’ competition organised by the Museum of Modern Art in 1948, the Plastic Armchair (A-shell) and Plastic Side Chair (S-shell) were launched on the market in 1950 as the very first mass-produced plastic chairs in the history of furniture.

The Eames Plastic Chairs also introduced a new furniture typology that has since become widespread: the multifunctional chair whose shell can be joined with a variety of different bases to serve diverse purposes. As early as 1950, Charles and Ray Eames presented a series of bases that enabled various sitting positions. An especially striking model is the so-called Eiffel Tower base an intricate and graceful design made of steel wire that inimitably combines light, elegant forms with structural strength.

Today Vitra manufactures the comfortable seat shells of the Eames Plastic Chairs in polypropylene, while those of the Eames Fiberglass Chairs are produced in glass-fibre reinforced polyester resin. There is also a wide choice of bases and shell colours, along with upholstery options for some models. This allows customers to specify countless different combinations and to use the chairs in the widest range of settings from dining rooms, living rooms and home offices to office workspaces and conference rooms; from restaurants and cafs to break rooms and cafeterias; from waiting areas and auditoriums to terraces and gardens.

In 2016, Vitra added roughly 20 mm to the base height of the Eames Plastic Chairs DSX, DAX, DSR, DAR, DSW and DAW while adapting the seat geometry accordingly.

Reviews

Clear filtersThere are no reviews yet.